In this article, I would like to show you a simple test to help you determine whether your material is suitable for a given pattern. We will take a look at how to determine the elasticity of a fabric.

Elastane, Spandex, Lycra...

Once upon a time, all fabrics were woven. Simple looms were used to weave weft threads through rows of warp threads creating a fabric. Different types of fabric weaves are created by different patterns and combinations of weft threads and warp threads.

The textile fibers were of natural origin. There were plant fibers (flax, hemp, cotton...) and animal fibers (sheep wool, alpaca wool, etc.).

The first knitting "machines" began to appear in the Middle Ages. However, knit, as we know it today, is a relatively new thing. Fabrics that are elastic because they are made on a knitting machine, are a twentieth-century invention and their use has only become widespread in the second half of the 20th century. Our great-grandmothers did not know about the knits, while we now use them every day.

Synthetic textile fibers also appeared in the first half of the 20th century. That was a huge breakthrough.

Because thanks to the first synthetic fibers we now have things such as spandex, Lycra, and other elastic fibers.

"Spandex" is an anagram of the word "expands".

So, what is the difference between Lycra, Spandex, and Elastane?

Let’s start with this: “elastane” is the common name for any elastic fiber. Lycra is one of the types of elastic fibers (it’s one type of elastane). Spandex is the same thing as elastane. Term “elastane” is mostly used in Europe, but in North America “spandex” is more common.

“Woven fabric = Inflexible and Knits = Elastic”? Well, not always.

Let's look at it this way. We have two basic types of fabrics - woven fabrics and knits. I described their differences here: Woven fabrics are inherently inflexible and knitted fabrics are inherently elastic.

Woven fabrics, as I have said, are made by weaving warp and weft threads. They are inflexible in their simplest form. Think of them as uncooked spaghetti. When you put it in front of you, you can see its final length. The length remains fixed, you can try to stretch the spaghetti as you wish, but its length will not change.

But the knits have fibers that are looped one after the other. Now imagine the cooked spaghetti, or a whole plate of cooked spaghetti. They are intertwined in different ways. When you pull on both ends of your spaghetti, the spaghetti straightens up and its length (as opposed to the original tangled position) expands. That’s why the knitted fabrics are flexible.

Surely you can easily imagine a classic hand-knit sweater. When you look closely, you can see individual yarns that are intertwined in loops. When you pull on it, yarns straighten, and sweater stretches. But when you pull on a single piece of yarn it won’t stretch. The elasticity is due to the entanglement of individual yarns.

So now we know that fabrics that are made on knitting machines (not weaving machines - looms) are inherently flexible. As with the woven fabrics, there are many different types of knits.

Various simple and complex patterns are used to create different types of knits. For example, we have a single-faced knit (its edges twist), double-faced knit (its edges do not twist), a tracksuit fabric (with typical loops on the reverse side), and so on.

If you've ever held a 100% cotton single-faced knit, 100% cotton double-faced knit and 100% cotton tracksuit fabric, you may already know what I mean. Although there are no elastic fibers in any of the three substances, they are elastic. A single-faced knit is the simplest type of a knit and since its “entanglement” is the simplest, this type of fabric is the most flexible in its basic form. Double-faced knit is less elastic and elastane-free tracksuit fabric has very little elasticity.

Elastic fibers are added to make the knits even more elastic.

Picture your spaghetti again. First the hard, uncooked one. It's on your table and there's nothing special about it. Now, instead of this spaghetti, imagine a rubber band of the same length. It is clear that if you pull on both ends of dry spaghetti, nothing happens. But when you pull both ends of the rubber band...? Boom! - Band stretches and suddenly you have some extra elasticity.

The elastic fibers are opening up a whole new world. When you add these fibers to the woven fabric, you suddenly have a woven fabric that is elastic (less than knit, but elastic). Tight jeans, tight pencil skirts, close-fitting evening dresses - these are exactly the pieces of clothing best sewed using woven fabrics (because they are strong and hold shape) with an addition of elastane (so that you can move).

Now imagine the wonders that elastane does with knits! Classic sweater will stretch out eventually. After some time and several washing cycles, it will become a formless something. So, in order to make the fabric elastic and help it to return to its original shape after stretching, we add some elastane. Thanks to its elasticity, it protects other fibers and extends their life.

Why use knits with elastane?

Elastan dodává látce více pružnosti a zároveň druhotně zpomaluje opotřebování ostatních vláken. Takže legíny hned po prvním nošení nebudou mít vytahaná kolena a u triček nebudou vytahané lokty.

Elasticity of the fabric

In the women's wardrobe (especially) you will find many pieces that need a great deal of flexibility. I’m talking about swimsuits, panties, leggings, or a turtleneck that we have to pull over our heads.

Let’s take a closer look at that turtleneck. You want it to hug your neck closely, so it needs to be just a little bit bigger than circumference of your neck. At the same time, you need to be able to stick your head through the neck opening so that the fabric has to be elastic.

I will work with a neck circumference of 36 cm and a head circumference of 54 cm.

36 centimeters is 100% of our neck circumference for the turtleneck, so 3.6 centimeters is 10% of this value.

The fabric must be able to stretch by 18 cm (54 cm - 36 cm = 18 cm) so you can pull the turtleneck over your head.

If 3.6 cm is 10%, then 18 cm is 50%

(18 cm / 3.6 cm = 5 -> 5 x 10% = 50%)

This means that the fabric needs to have elasticity of at least 50% for you to be able to stick your head through the neck opening. This does not mean that it should have 50% elastane content, but that it should be able to stretch by 50%. If it were to have 100% elasticity, it would mean that it would be able to double its length when stretched. We need to stretch our fabric by 50% - that’s 1.5x its length at rest.

I'm not going to explain it further, because I'm afraid of making it unnecessarily complicated. :)

How to determine the elasticity of a fabric

I have prepared a very simple tool - elasticity scale - that will help you easily determine the elasticity of any fabric.

Simply download this template/scale here:

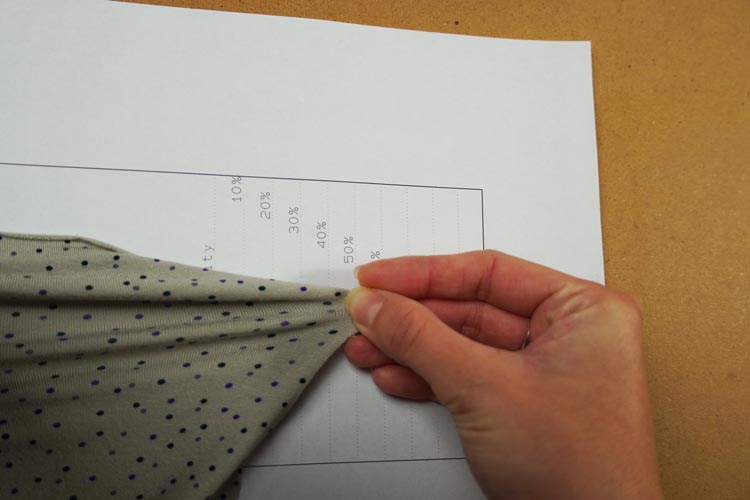

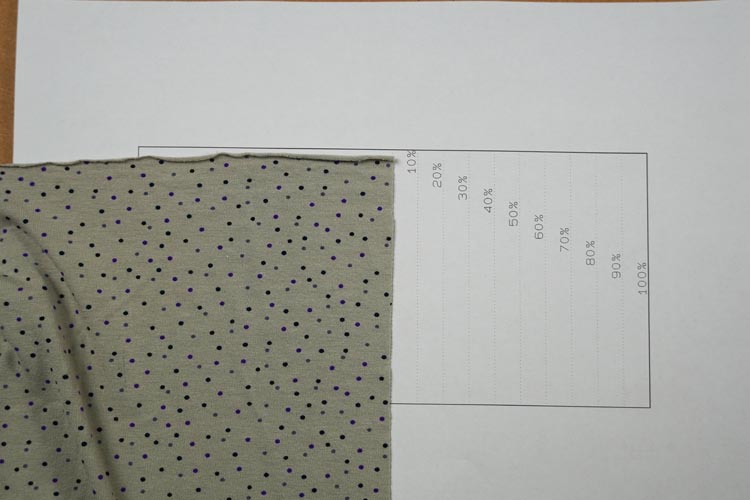

How to use the elasticity scale

Print the PDF document (ideally using 100% scale, but even if there is some distortion it does not matter, as the proportions will stay the same).

Prepare a piece of the fabric you want to test.

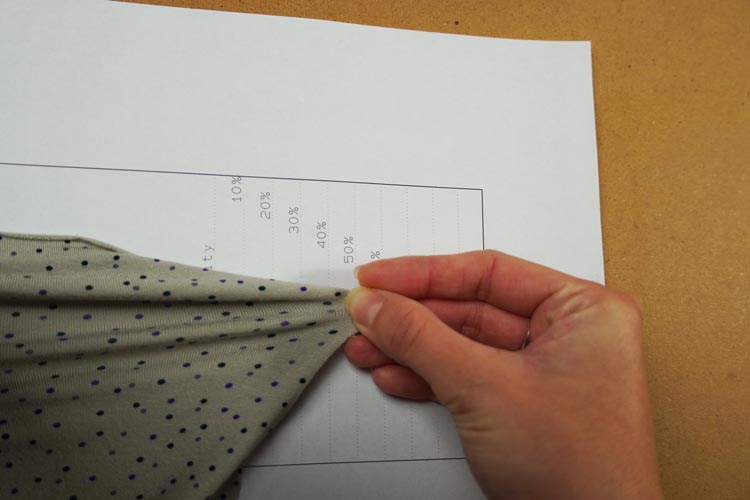

Lay your fabric on the page so that its edge is aligned with the leftmost dotted line.

Now clamp down on the fabric along the leftmost continuous line (frame of the scale) with your finger or side of your hand (push with the whole finger, not just the tip).

Now hold the other side of the fabric and stretch it over the dotted lines to find out its elasticity.

Why it is good to know the elasticity of the fabric?

For example, think of panties. You have a panties pattern; you have chosen a suitable size according to the size chart and you have your fabric. Is your fabric suitable for this particular pattern? Measure hips circumference on the pattern (the widest part of the panties) and on your body. Compare the two values (as in the example above, comparing the neck circumference and the head circumference). You will find out how much the fabric needs to stretch so that the panties (of this particular size) fit you. Compare the calculated (the lowest possible) elasticity with the actual elasticity of your fabric using your paper scale.

And what if the elasticity is significantly higher/lower than you need it to be? You can try to choose a different pattern size. For example, if you have a pattern for a close-fitting T-shirt and a fabric that has a low elasticity, then there is a great chance that the T-shirt will be too tight. In this case, you can try to move one size up. By comparing the elasticity, you have just avoided an unpleasant surprise.

I hope that today's article was interesting for you. If you liked it, I would be glad if you let me know about it in the comments. Also do not hesitate to post your questions there (if you have any), I will be happy to answer them.

Have a nice day, Peťa